Color Emtpy Capsule with rich color options

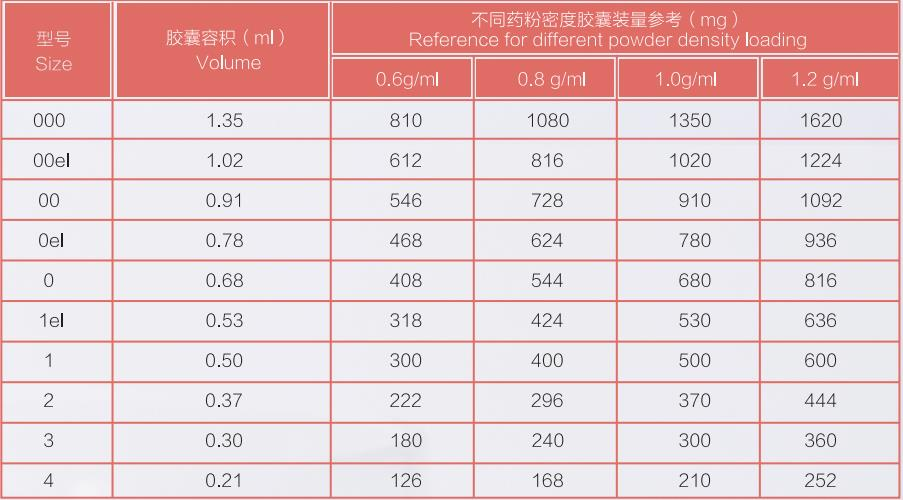

Filling capacity

The most popular size in global is #0, for example, if the specific gravity is 1g/cc, the filling capacity is 680mg. If the specific gravity is 0.8g/cc, the filling capacity is 544mg. Best filling capacity requires suitable capsule size in order to perform smoothly during filling process.

The Capsule Filling Capacity table is shown as below. Size #000 is our largest capsule and its filling capacity is 1.35ml. Size #4 is our smallest capsule and its filling capacity is 0.21ml. The filling capacity for different size of capsules is depends on the density of capsule contents. When the density is bigger and the powder is finer, the filling capacity is larger. When the density is smaller and the powder is bigger, filling capacity is smaller.

If filling too much powder, it will let capsule become un-locked situation and content leakage. Normally, many health foods contain compound powders, so their particles have different sizes. Therefore, choosing specific gravity at 0.8g/cc as a filling capacity standard is much safer.

Feature

Our two-piece empty hard capsules are GMO free and derive from completely natural sources. All capsules are made in c-GMP & ISO & BRCGS standard workshop.

Special colors will be available with minimum order quantity requirement.

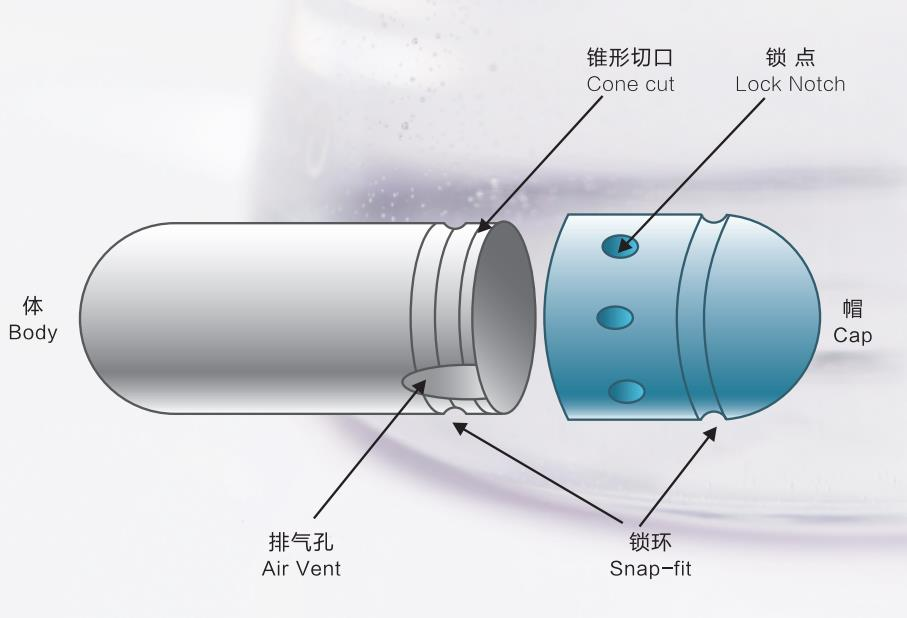

Capsule structure

End of Cap

It is the main part bearing closing pressure during locking motion. Its thickness must bear closing force of the filling machine to prevent dent.

Hemispherical End

This section also needs to bear closing pressure during locking motion.

Body Thickness

Thickness must be within specifications for enabling to perform smoothly during filling process and to have a close fit between the walls of cap and body.

Edges

Smoothness of cutting edges can affect the capsule filling performance.

Tapered Rim

The tapered rim design on the body allows for telescope-free encapsulation, especially on the high speed capsule filling machines.

Locking Rings

They are designed to be close-fitting during Locked status and to prevent from separation or content leakage.

Dimples

They are designed to gently engage with indented ring of the body during Pre-Locked status.

Air Vents

They are designed to release the compressed air inside capsule occurred during filling process.

Raw material

The origin of raw materials is approved as “Generally Recognized as Safe” (GRAS). Hence the quality of YQ colored empty hard capsules are safe and reliable.

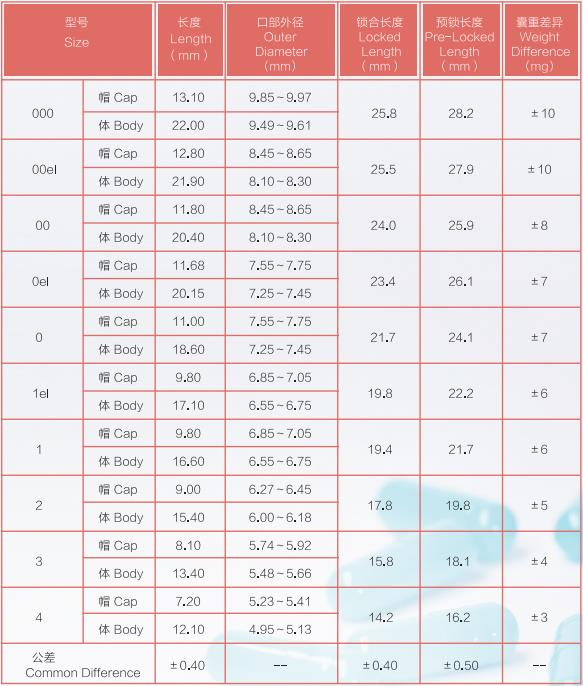

Specification

Advantage

1.Allergen Free, Preservative Free, Non–GMO, Gluten free, Non-irradiation.

2.Odorless and tasteless. Easy to swallow

3.Manufactured in accordance with NSF c-GMP / BRCGS guidelines

4.Excellence filling performance on both high-speed and semi-automatic capsule filling machine

5.YQ color empty hard capsule has a wide range of applications for pharmaceutical and nutraceuticals industry.

Certification

* NSF c-GMP, BRCGS, FDA, ISO9001, ISO14001, ISO45001, KOSHER, HALAL, DMF Registration